Sector 60, Noida, Uttar Pradesh

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

Preferred Buyer From

| Location | Worldwide |

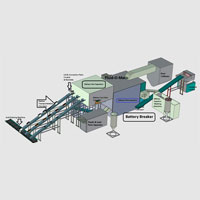

The Triple Stage Battery Cutting Machine, which we offer, is manufactured in confirmation to the established industrial standards. We are amongst the reliable Sources to source these Triple Stage Battery Cutting Machines. Also, this Triple Stage Battery Cutting Machine is manufactured using the leading-edge technology.

Details

- This machine has an automatic conveyor

- Battery is placed on the conveyor

- Width of Battery, need not to be set

- It can accommodate Battery up to Max. Width of 305mm (Most of Batteries are less than this)

- This machine has three Blades for Cutting

- Cutting heights of all the three blades can be set at independent heights by turning Rotary wheel (This wheel is visible in picture of machine)

- Scale is provided to set the height of cutting from bottom. Conveyor takes the Battery into machine for cutting.

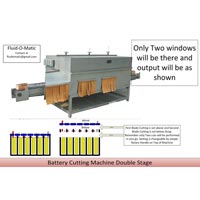

- First Cutting is set above lid so any battery which has more height than normal automotive batteries like Standby Batteries i.e. IT-500, Jumbo, etc. will be cut and that portion ejects out from first window

- Second Cutting is set normally at sealing line of automotive battery lid and third cutting is set below strap. During Cutting of Battery dust is confined inside of covers because cutter is enclosed. Max. Of Automotive Batteries have approximately same height, say +-10 mm. Cut Lid ejected out of first window and Strap portion of battery ejects out form second window. Remaining Battery will come out of machine on Conveyor. Machine can be provided with wheels so machine is used to unload battery at the same time cutting is performed.

- This saves exposure of workman from Lead Dust; increases efficiency of organization reduces lead time as well as increases liquidity of Funds. Plastic Containers can be sent for immediate disposal/recycling facility.

- Lead Dust is confined inside enclosure at the same time water jets are provided by pre-fitted Pump.

- Water is collected in the bottom tank

- This helps to separate Plastic Dust from Lead dust. Plastic dust floats and lead dust is precipitated at the bottom. Hence it becomes environmentally Sound Method to cut the Battery for further separation. Remember this Cut Battery can directly go to another attachment; we call it Acid Draining.

Situated in Noida (Uttar Pradesh), we have built a wealth of reputation for manufacturing, supplying and exporting the superior-grade Triple Stage Battery Cutting Machines across the globe. Attainable at market-leading prices, the Battery Slicer (Triple Stage) is distinguished for its hassle free functions for a long span without much upkeep. For utmost gratification of the clients, we dole out quality-tested Battery Cutting Machines in tailored specifications.

Specifications :

- Out Put Capacity : Two to Two and Half Ton/ Hour.

- Power Requirement : 16 Kw, 440 Volt, 3 Phases, 50 Hz.

- Man Power Requirement : Two no. unskilled Labor

- Operational Expenses for battery Breaking per ton : $ 2.10/ Ton approx

Description :

- This Machine has One Conveyor, Three Cutting Stations with one Bend Saw Blade each. Conveyor is used to feed the batteries into machine and Cuts off batteries at three respective set heights, as set by the operator. Blades are water cooled. After Cutting operation, Cut batteries are transported out of the machine by conveyor. Cut (Sliced Off) Top of battery is ejected out automatically from first window and Connection Strap and part of Container from Second Window and third blade as stand by so during slicing off if one of the blade become blunt then another station is utilized and production is not interrupted. Other option is if Bigger battery with more height is fed then it can be sliced off into four Pieces.

- Maximum Height of batteries can be fed to the machine is 600 mm and width being 305 mm.

- Fume are collected and restricted by the Enclosed Body of Machine. No human exposure is involved in Cutting operation.

- Exposure of acid fumes and lead meet best environmental practices in the world

- No. Adjustment of Width is required.

Operation of Machine : Batteries are placed on the moving conveyor. Top of Batteries is sliced off by high Speed Bend Saw. There is one Bend Saw with height adjustment to set Cutting (Slicing) Height. Height is set manually. Sliced off Lid from first window is ejected out. Then battery moves to second cutting Blade, here Connection Strap and Part of Container is Sliced off which is also ejected out from Second Window. If more height battery is sliced off then part of Plates and Container is also sliced off and Remaining Part of battery is transported by the conveyor to other end of the machine, where it is toppled into Acid Draining Attachment.

Output of Machine :

- Battery Top

- Connection Strap with Container Part

- Part of Plates and Container

- Remaining part of Battery.

- Acid Drained out in to Acid tank.

Size of Machine : 2200 mm (H) X 2200 mm (B) X 6150 mm (L) Approx.

Raise your Query

Hi! Simply click below and type your query.

Our experts will reply you very soon.